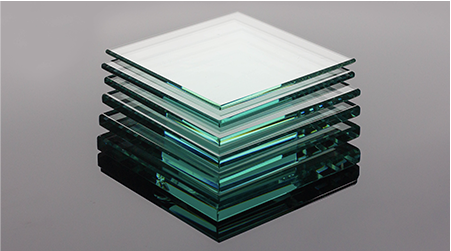

for rice husk silica with

99.99% SiO2 content

products obtained from

non-polluting process

characteristics for

specific applications

compared to other

products in the market

for adopting eco

products into production

customized based on

customers' needs

completely void of any

crystalline content

for rice husk silica with 99.99% SiO2 content

products obtained from non-polluting process

characteristics for specific applications

compared to other products in the market

for adopting eco products into production

customized based on customers' needs

completely void of any crystalline content

Collection

& Cleaning